Our Patented CellTech Panels Hold Up Where Aluminum Does Not.

Constructed from patented CellTech panels, our trailers are unlike any other trailer on the road.

- High Bending stiffness to weight ratio

- Extremely durable (10 year warranty!)

- Made in the USA

- Patented

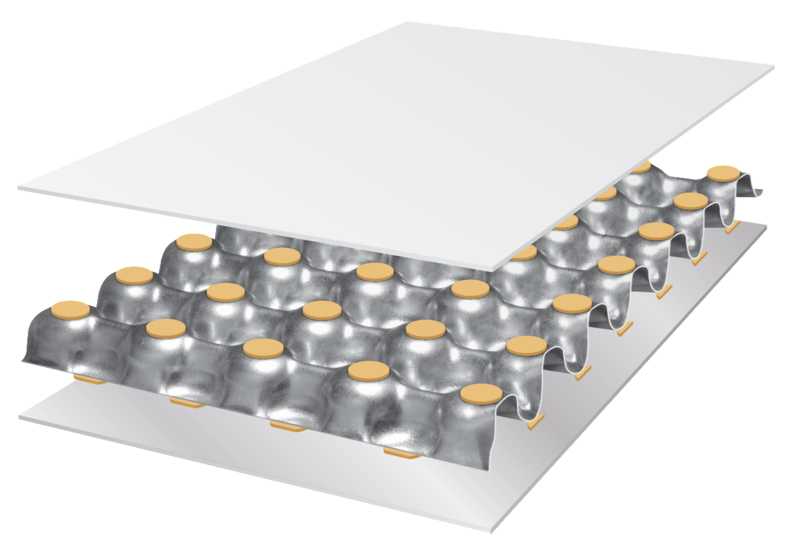

- Skins are hot-dipped galvanized 80ksi steel with an anti-corrosion primer and poly topcoat

- Core is hot-dipped galvanized steel bonded to the skins with toughened structural adhesive

- Hot dipped galvanized 80ksi steel

- Anti-corrosion primer

- Polyester topcoat

- Hot dipped galvanized steel

- Toughened structural adhesive

Ladder

Roof load capacity 1,000 lbs distributed load

Roof Rack

Decking Load Capacity is 500lbs Per E-Track

Shelf Load Capacity is 500lbs Per E-Track

Ramp Load Capacity is 3,000lbs

The Toughest Trailers On The Planet.

Constructed from patented CellTech panels, our trailers are the first trailers built truly to a professional standard.

- Integrated Roof Rack with a 1,000 lb distributed load capacity

- Integrated Ladder for easy roof access

- Integrated wall tracks (E-tracks) for easy installation of shelves, cabinetry, work benches and more!

- Transport wheeled equipment easily with a 3,000 lb capacity integrated ramp

- Versatile access with a standard side door

Thoroughly tested panels for years of rugged use.

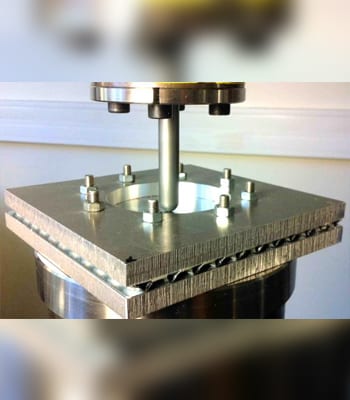

Puncture/Dent Tests

CellTech sandwich panel materials are tested for dent and puncture resistance to meet the application’s requirements. We work with our customers to select the type, gauge, and coating of the face sheet materials and then optimize the sandwich thickness to ensure we have a finished product that meets or exceeds expectations.

Compression Tests

Bending Tests